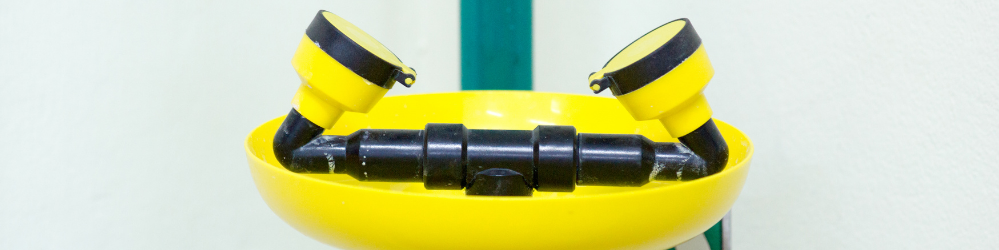

Accidents Can Happen – And Eyewash Stations Need to be Quickly Found

Emergency eyewash signs help employees to find this important equipment when accidental exposure to harmful chemicals occurs. Time is of the essence when a person needs to use an eyewash station, as injuries could be severe.

OSHA Rules on Eyewash Stations

The OSHA regulation for eyewash station safety signs reads as follows:

1910.151 C Where the eyes or body of any person may be exposed to injurious corrosive materials, suitable facilities for quick drenching or flushing of the eyes and body shall be provided within the work area for immediate emergency use.

1910.1200(b)(3)(ii) Employers shall maintain any material safety data sheets that are received with incoming shipments of hazardous chemicals, and ensure that they are readily accessible during each work shift to laboratory employees when they are in their work areas;

OSHA refers all other concerns about emergency eyewashes to the American National Standards Institute (ANSI) and the International Safety Equipment Association (ISEA).

ANSI/ISEA Z358.1: The American National Standard for Emergency Eyewash and Shower Equipment standard, most recently updated in 2014, is one of the best sources for best practice guidelines for the selection, installation, operation, and maintenance of the equipment.

Better Eyewash Station Signs and Placement Rules

Because of our involvement with writing the ISO standards for safety signs, we understand how safety equipment location sign systems are meant to be designed and installed. Picture the risk situation you’re trying to address. There is an immediate need to find the eyewash stations in your lab, your plant’s maintenance department, or in your forklift battery charging area. The optimum situation is that the emergency eyewash station is situated where everyone in every corner of that area can see the equipment, or see the sign mounted above the equipment. But obstacles, partitions, posts, and corners in rooms exist. So the best safety practice is as follows:

- Post an emergency eyewash sign above the actual equipment.

- Then install directional versions of the same sign (which point toward the direction to the equipment) wherever people cannot actually see the equipment or the “above-the-equipment” sign.

Additional Emergency Eyewash Identification Advice

According to ANSI/ISEA Z358.1, the location of each emergency eyewash should be identified with a highly visible sign in a well-lit area. The sign should be in the form of a symbol that doesn’t require workers to have to read the language to understand it. Ideally, one of the eyewash station signs should be atop the location of the eyewash station or kit's location, with other directional signs dispersed throughout the facility as appropriate.

Most commonly, it’s recommended to install large green projecting signs stating “emergency eyewash” with large white font. The size of letters on eyewash station signs should be sufficient to be easily read across your facility. The International Organization for Standardization’s ISO 7010 official graphical symbol for emergency eyewash signs is a green background with white graphics of an eye above running water coming out of a showerhead accompanied by a first aid cross. However, ISO does note that the first aid cross can be replaced with another element that is appropriate to the cultural requirements of the workplace.

Selecting a sign can include several different shapes, sizes, and materials, including having it protrude from a wall end or corner, enabling people to locate it from many angles. To combat the dark, some signs are even designed with photoluminescent materials to be visible in all situations.

We carry all the variations you need for each of these types of signs.