Take advantage of our best in class services for machine builders and machine users. These solutions complement our safety label and safety sign product offerings. Don't see what you’re looking for? We're listening – contact us today!

OEM Safety Solutions

OEM Safety SolutionsApply product safety best practices to identify and mitigate risks throughout your product's lifecycle. Our team of experts help remedy and prevent safety and strategy issues that machine builders typically face from development to market.

Learn More Workplace Safety Solutions

Workplace Safety SolutionsMake safety a priority with effective solutions to identify and manage hazards associated with your machinery. Our TÜV certified safety engineers are ready to help with your machine safety, guarding, risk assessment, and training needs.

Learn More Label & Sign Services

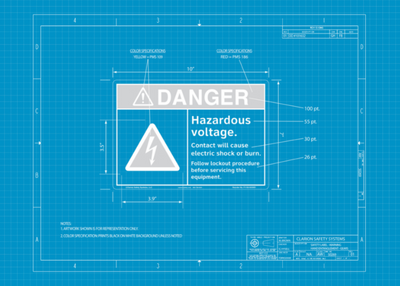

Label & Sign ServicesIn addition to our ready made safety products, get optimized safety communication techniques, custom designs, and personalized best practice label and sign recommendations for both domestic and international warnings.

Learn More

At Clarion Safety, we strive to not only help you reduce risk and protect people, but to provide the best customer service and ordering experience possible. For your convenience, we’ve compiled an area for you to access purchasing tools such as rush order information, quote requests, tax exemptions, and credit applications/payment terms.